GE T60 | Transformer Protection System

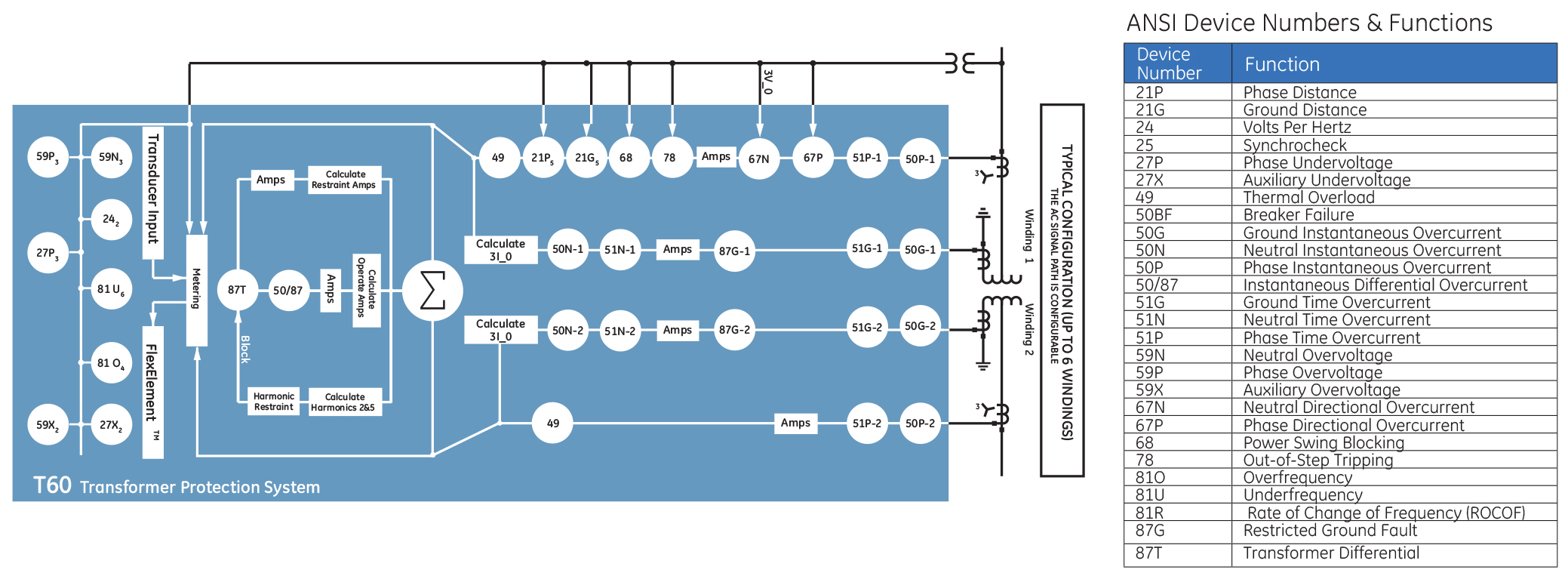

The T60 is designed for various power applications, including autotransformers, generator step-up transformers, split-phase, angle regulating transformers and reactors. It uses multiple current and voltage inputs to provide primary protection and backup protection of transformers, including differential, ground differential, five distance zones, phase, neutral, and ground overcurrent, under and overvoltage, under and overfrequency, over-fluxing, and breaker failure.

Applications

- Transformer asset monitoring using hottest spot, loss-of-life and aging factor

- Applicable for transformers with up to six windings in a ring bus or breaker-and-a-half configuration

- Reliable and secure protection for three-phase transformers, autotransformers, reactors, split phase and phase angle regulating transformers

- Stand-alone or component in automated substation control system

Key Benefits

- Secure high-speed protection for transformers, compliant with IEEE® C37.91

- Improved security for transformer energization and inrush provided through a superior adaptive 2nd harmonic restraint algorithm

- Sensitive ground fault protection provides low-impedance differential protection down to 5% of the winding to limit transformer damage

- Phasor Measurement Unit (synchrophasor) according to IEEE C37.118 (2011) and IEC® 61850-90-5 support

- Three independent fiber or copper Ethernet ports for simultaneous/ dedicated network connections with advanced 1 microsecond time synchronization via LAN with IEEE 1588 support

- Reduced relay-to-relay wiring and associated installation costs through high-speed inter-relay communications

- Increase network availability by reducing failover time to zero through IEC 62439-3 "PRP" support

- CyberSentry™ provides high-end cyber security aligned to industry standards and services (NERC® CIP, AAA, Radius, RBAC, Syslog)

- Advanced fault and disturbance recording, including internal relay operating signals, eliminating the need for redundant recording devices

- Integrated transformer thermal monitoring for asset management and maintenance optimization

- Complete IEC 61850 Process Bus solution provides resource optimization and minimizes total P&C life cycle costs

Functional Block Diagram