MM300 | LV Motor Management Systems

The MM300 is a digital motor protection and control system, designed for Low Voltage motor applications. Flexible and powerful, the MM300’s protection

The MM300 integrates protection, control, automation, metering, diagnostics and multiple communication

protocols in a rugged compact device for low voltage motor applications. Designed for NEMA and IEC Motor

Control Centers, the MM300 delivers superior protection and control to extend equipment life and maximize

process uptime

KEY BENEFITS

- Full-featured protection for low voltage AC motors

- Advanced automation capabilities for providing customized protection and integrated process control

- Advanced FlexLogic™ reduces requirement for local PLC's

- Reduced space requirements through integration of multiple devices

- Application flexibility with multiple I/O options and programmable logic options (FlexLogic™)

- Enhanced troubleshooting tools including sequence of event records and waveform capture

- Powerful communications including Serial, Ethernet, Profibus, and DeviceNet protocols

- Small form factor and remote display options designed to fit in MCC buckets

APPLICATIONS

- Low Voltage three phase AC motors

- MCC or stand alone panel mount applications

- Reversing and Reduced Voltage applications

- Applications requiring Automation or Control i.e. conveyor systems or well recovery pumps

- IEC or NEMA class motors

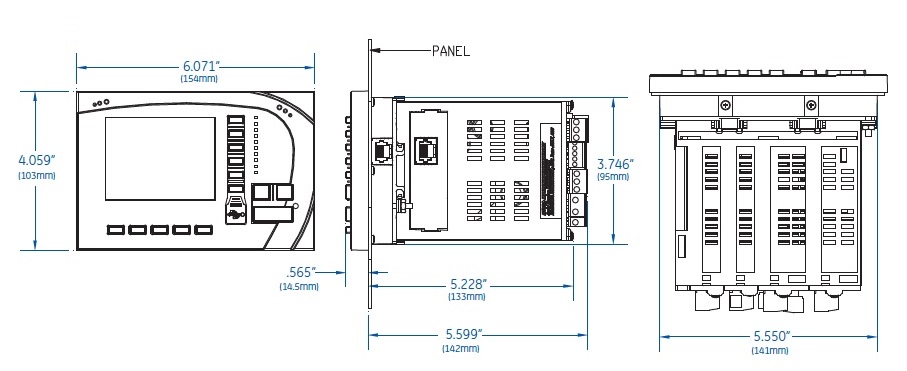

DIMENSIONS

FEATURES

Protection and Control

- Enhanced Thermal Modeling

- Mechanical Jam / Stalled Rotor

- Undercurrent

- Underpower

- Acceleration Time

- Current Unbalance

- Ground Fault

- Sensitive Ground Fault

- Phase Overvoltage / Undervoltage

- Auxiliary Undervoltage

- Phase Reversal

- VT Fuse Failure

- Thermistor

- RTD Overtemperature

Metering & Monitoring

- Metering - current, voltage, power, energy, frequency, RTD, Thermistor

- Oscillography – analog values at 32 samples/cycle and digital states

- Event Recorder - Up to 256 time tagged events with 1ms res.

- Advanced device health diagnostics

Communications

- Networking Interfaces - Two Wire RS485, RJ45 Ethernet

- Multiple Protocols (Modbus RTU , Modbus TCP/IP, Internally powered Profibus, ODVA compliant DeviceNet)

- Programming Ports - USB, RS485

- Network Time Protocol (when ordered with Ethernet) User Interface

- Control panel with 12 status LED's, Motor Control and function keys

- Color HMI Display featuring a full color graphical display, Motor and system status LED's, USB programming port and motor control keys.

EnerVistaTM Software

- State of the art software for configuration and commissioning GE Multilin products

- Graphical Logic Designer and Logic Monitor to simplify designing and testing procedures

- Document and software archiving toolset to ensure reference material and device utilities are up-to-date

Automation

- Programmable FlexlogicTM option

- Starter Control

- Process Interlocks

- Programmable inputs and outputs

- Undervoltage Auto-restart