Capacitor

In the event of overvoltage, thermal overload or ageing at the end of the capacitor‘s useful service life, an increasing number of self-healing breakdowns may cause rising pressure inside the capacitor.

Protection against Overload and Failure at the end of Service Life

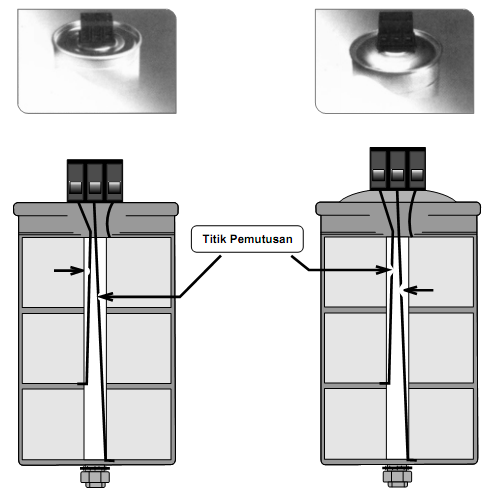

In the event of overvoltage, thermal overload or ageing at the end of the capacitor's useful service life, an increasing number of self-healing breakdowns may cause rising pressure inside the capacitor. To prevent it from bursting, the capacitor is fitted with an obligatory «break action mechanism» (BAM™). This safety mechanism is based on an attenuated spot at one, two, or all of the connecting wires inside the capacitor.

With rising pressure the case begins to expand, mainly by opening the folded crimp and pushing the lid upwards. As a result, the prepared connecting wires are separated at the attenuated spot, and the current path is interrupted irreversibly. It has to be noted that this safety system can act properly only within the permitted limits of loads and overloads.

With rising pressure the case begins to expand, mainly by opening the folded crimp and pushing the lid upwards. As a result, the prepared connecting wires are separated at the attenuated spot, and the current path is interrupted irreversibly. It has to be noted that this safety system can act properly only within the permitted limits of loads and overloads.

MKPG Module 3 Phase New Generation of Dry Type Capacitor

Environmentally Friendly

The gas in our MKPg-Capacitors is inert and entirely harmless to environment. When disposing of the capacitors, no liquids or toxic gasses need to be considered.

Leakage Proof

Leakage of gas is extremely unlikely if the capacitors are handled and operated properly. It is possible to mount these capacitors in any desired position. However, should leakage occur, the leaking gas would escape into the atmosphere causing no undesirable effects to the adjacent equipment, e.g. damage, pollution, or staining

Less Weight

By using gas, we are reducing the weight of a capacitor on average by 15% compared with resin or oil filled capacitors. This makes transportation and handling of the units easier. It also supports the concept of mounting the capacitors in almost any position.